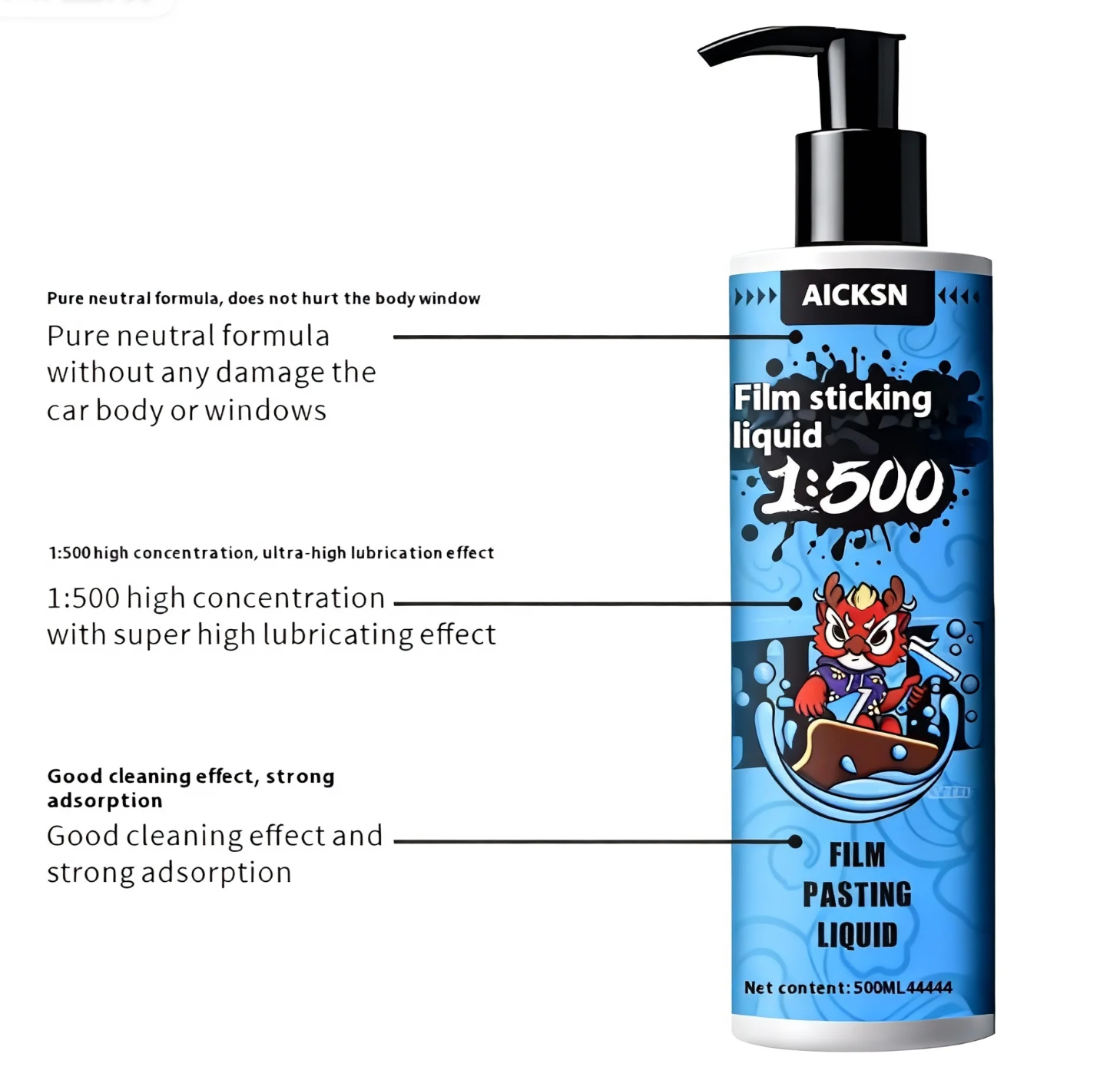

Vinyl Wrap Application Liquid For Installation

- AICKSN

- China

- Less than seven days

- Large quantities in stock

During wet installation, Liquid Gloss solution is essential. It ensures smooth positioning of the film, prevents corrosive damage to adhesive layers, allows easy bubble removal, and slows water evaporation. This ensures a seamless, durable finish.

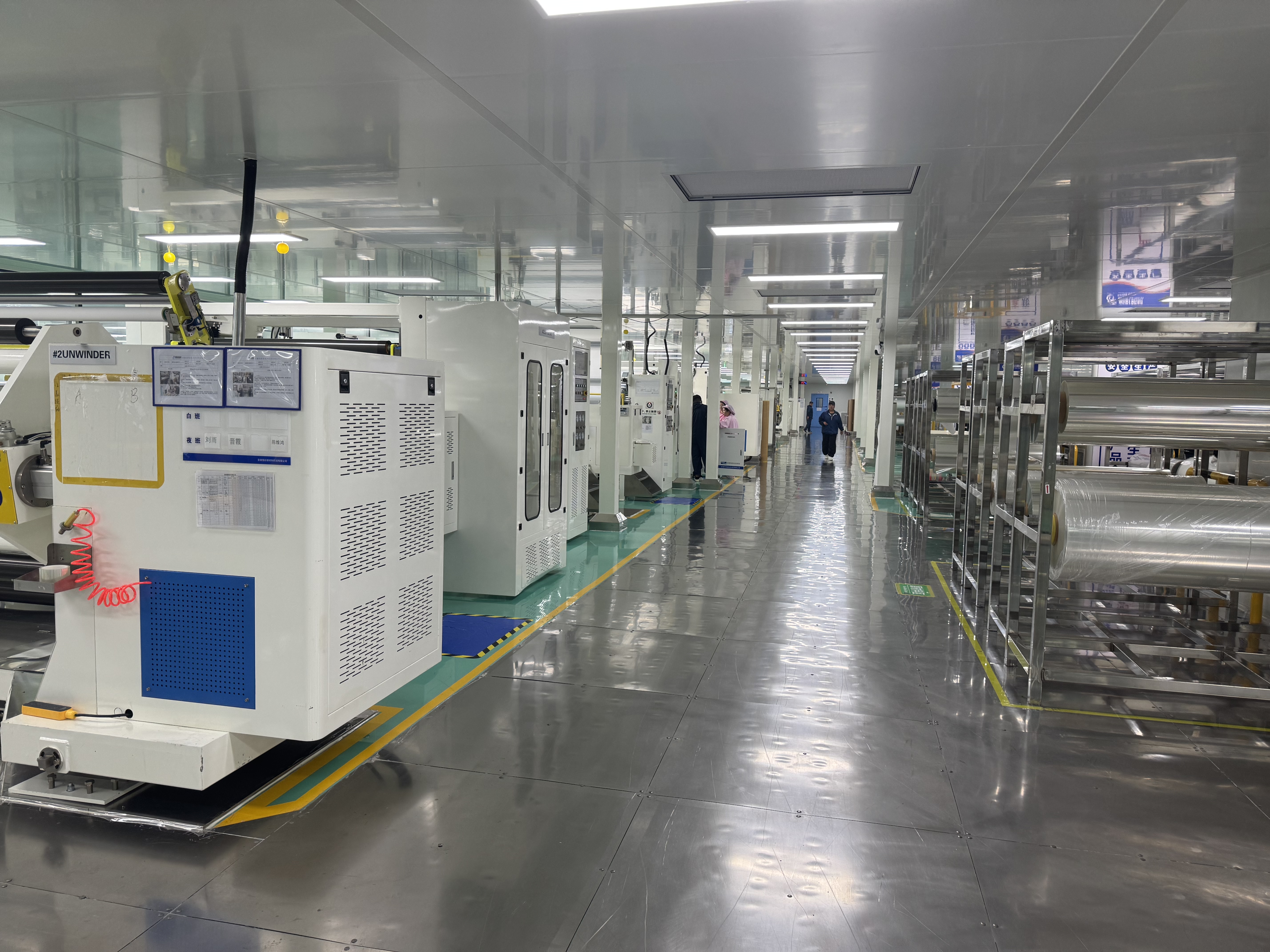

AICKSN Professional Paint Protection Film Installation Solution: A "Liquid Engineer" for Perfect Invisible Film Application

Paint Protection Film (PPF)application, which is called an "invisible car wrap", is an advanced topicof film technology itself, and the technology of the film is, of course, one of the most important aspects. Nonetheless, there is a professional installation solutionthat can be considered as the real protagonist and which is responsible for how well the PPF will be "invisible", how long it will keep the car protected, and how flawlessit will be. AICKSN acknowledges the fact that the installation processcan be accountable for about 90% of the performanceand the visual appealof a top-tierand rather expensive PPF. That is why the AICKSN Professional PPF Installation Solutionis not a mere soapy water. It is a carefully crafted "liquid application system"derived from fluid dynamics, surface chemistry, and adhesion science. It is an "extended hand"of the installer and an "intelligent bridge"between the film and the paint that every application becomes a transformation of complex challengesinto stable, efficient, and perfect results.

After the protective film is placed on the paint surface and the installation solutionis sprayed, the adhesive layerof the film and the car paintwill be separated by a stable aqueous lubricating film. This makes the large and substantial protective film able to move on the paint surface with almost no frictionat all, just like a hovercraft. The AICKSN installation solution is packed with highly efficient surfactantsand interface displacement agents. Besides providing lubrication, these agents also work as detergents, and hence they encapsulateand effectively remove the dust, oils, or leftover prep chemicalson the paint surface after the pretreatment process.

AICKSN designs the evaporation curveof the solution by introducing volatility regulators.

The suspension-stabilizing componentsin the solution can reliably encapsulate and isolatemicroscopic bubbles and dust particlesthat are unavoidable during application, preventing them from randomly adhering.

Formulation Science: Perfect Chemical Cooperation Under Balance

The high performanceof the AICKSN installation solution is achieved due to the accurate compositionof various operative parameters; each component has a clear mission.

Base Medium: Ultrapure Deionized Water

Deionized wateror reverse osmosis purified wateris certainly the best choice as the solvent base. It removes ionssuch as calcium, magnesium, and chlorinethat are contained in tap water and are known to cause water spotsand, hence, negatively affect the clarityof the film, which may also result in an adhesive or car paint reaction.

Core Lubrication and Surface Modification

High-Polymer Lubricants(e.g., Polyethylene Oxide): Offer durable lubrication, facilitate squeegee motion, and prevent scratcheson the film surface.

Composite Surfactant System: Provides complete cleaning, wetting, and surface tension reductionproperties since they allow the medium to quickly spread, dissolve, and penetratethe finest corners.

Volatility Regulation and Application Aids

Alcohols(e.g., Isopropyl Alcohol): Limited to a certain percentage, they play a role as detergents, facilitate the moisture evaporationprocess at the beginning, and, along with other light organic solvents, balance the overall volatilization speed.

Humectants(e.g., Glycerin): Adding them in a very small quantity keeps the liquid from evaporating too fastin a dry environment, and hence, the application surface is kept moistand the working timeis extended.

Protection and Compatibility Additives

pH Buffer System: The system stabilizes the solution in a neutral to slightly acidic pH range (pH 6-7), which makes it compatiblewith most automotive clear coatsand PPF adhesivesin terms of chemical properties, and it keeps the clear coat from getting dullor the adhesive from breaking downdue to excess acidity or alkalinity.